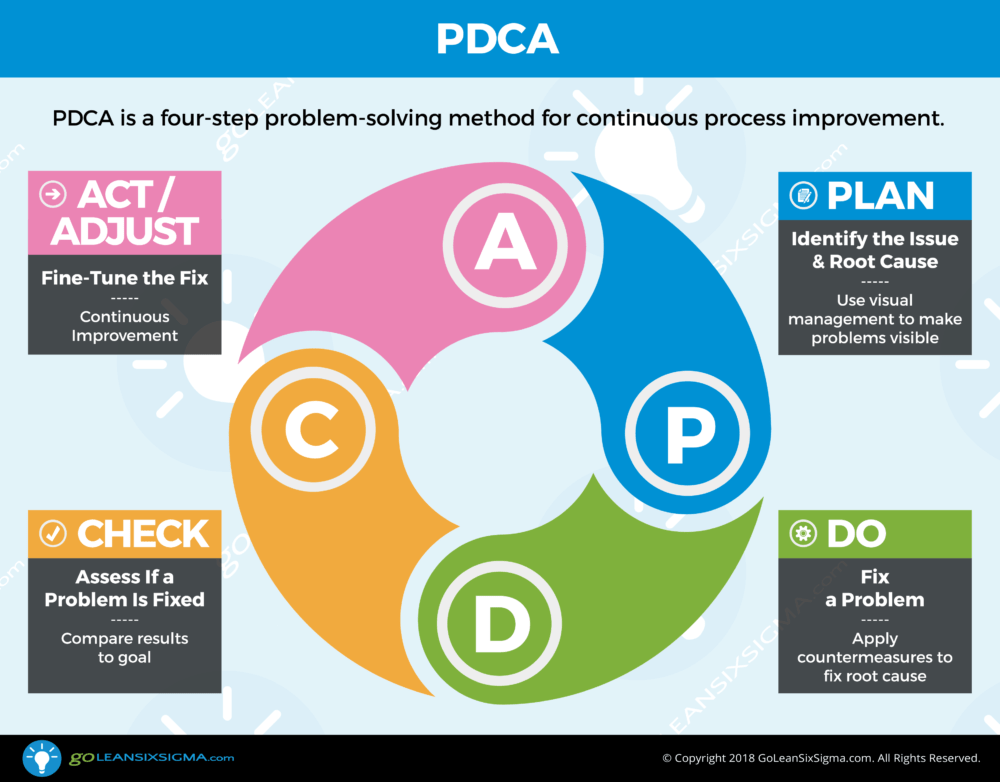

PDCA is an acronym for Plan, Do, Check, and Action, and is a method of continuously improving operations and businesses.

There are many companies and businessmen who use this method because it can lead to improved operational efficiency and business development. On the other hand, there are many cases in which the system is not being operated effectively and “I don’t see much results.”

In this article, we will explain the overview of PDCA, the four processes, advantages and disadvantages, and points for effective implementation. Please read this article and use it as an opportunity to improve your work efficiency and develop your business.

What is PDCA?

Many people involved in business have probably heard of the term PDCA, but some may think, “I know the word, but it’s difficult to explain.” First, I will explain the meaning and overview of PDCA.

Methods for continuously improving and improving management operations

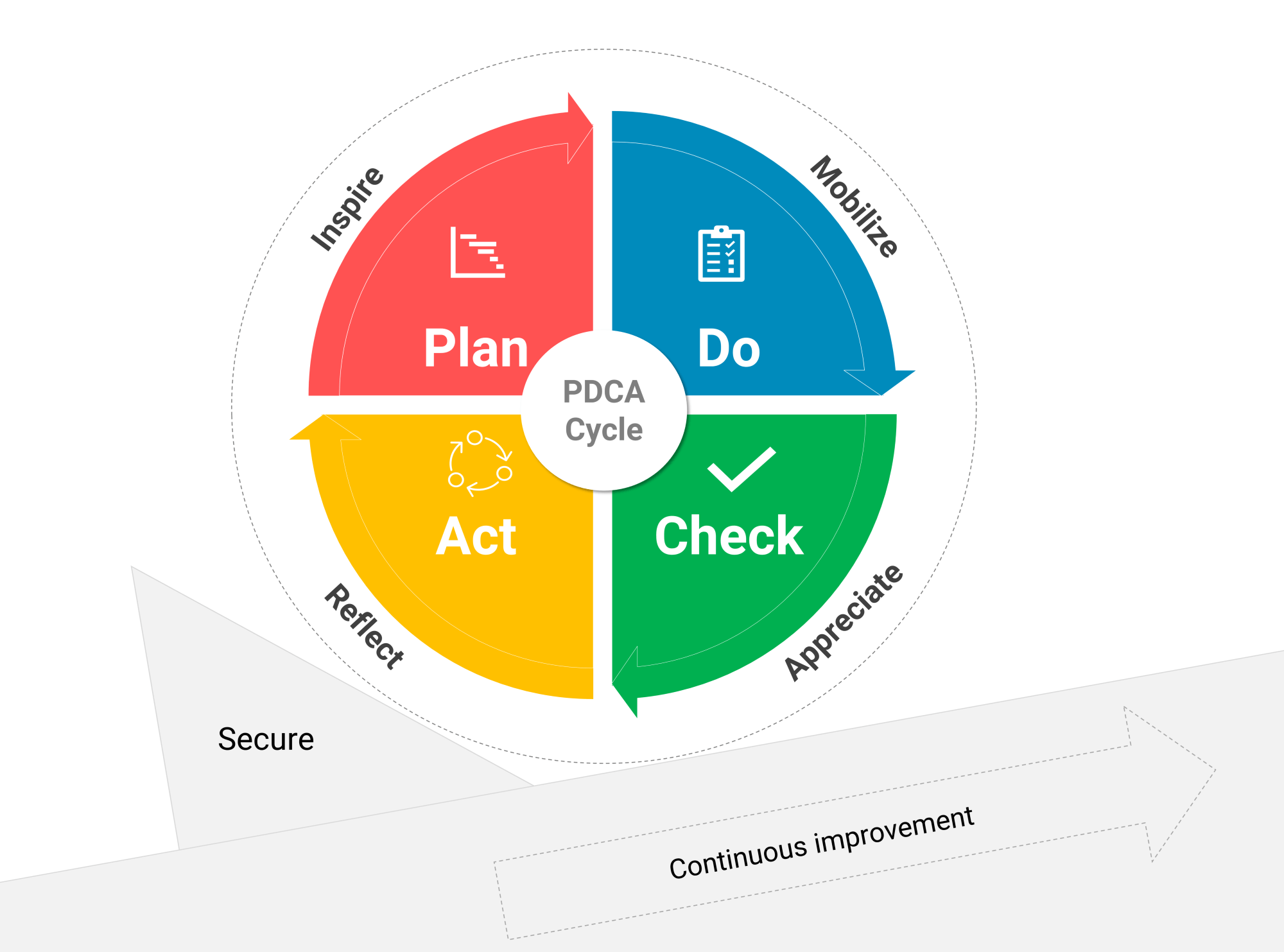

PDCA is an acronym that stands for Plan, Do, Check, and Action. PDCA is an acronym that stands for Plan, Do, Check, and Action. It is a method of implementing and improving improvements.

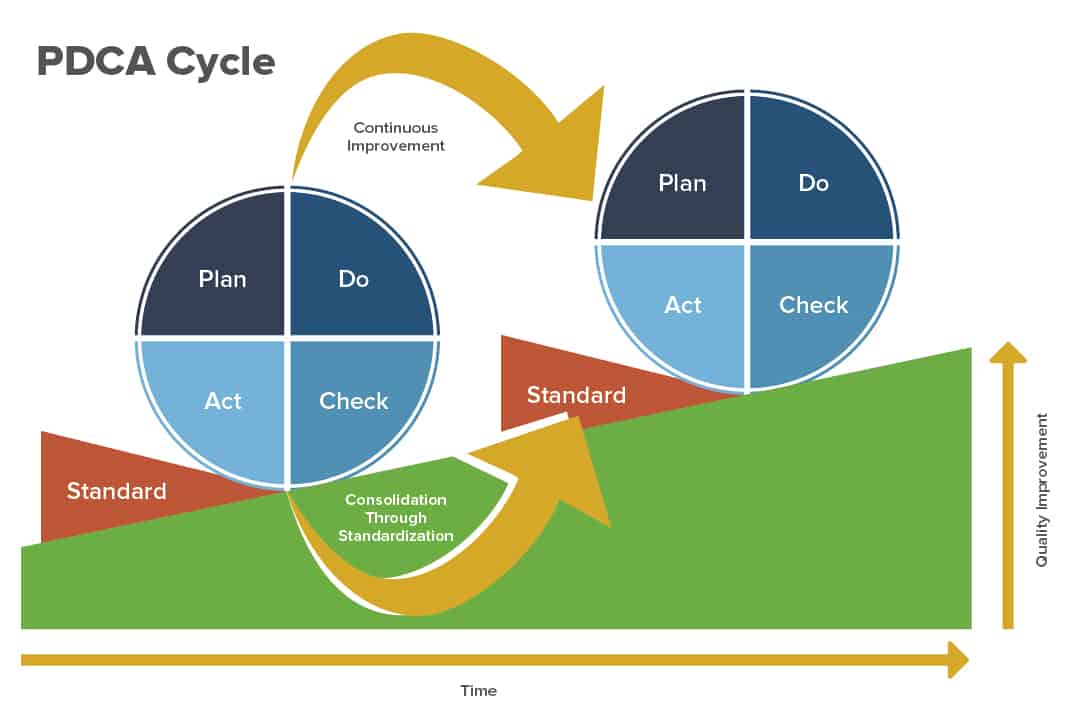

A cycle goes from P (plan) to A (improve), and once you get to A, you go back to P. This series of steps is called the “PDCA cycle” because this process is repeated and repeated.

What kind of scene is it used in?

PDCA was proposed by American statisticians William Edwards Deming and Walter Shewhart in the 1950s. Today, Japanese companies are also actively incorporating this method as a method of quality control. In particular, it is widely used in the Japanese manufacturing industry, which produces products that can be proud of around the world. By implementing PDCA, we are able to manufacture better products and develop our business.

PDCA is used not only in the manufacturing industry, but also in corporate marketing measures and recruitment operations, and is incorporated in a variety of situations.

4 processes

As mentioned above, PDCA involves four continuous processes. From here, we will explain the details of these four processes.

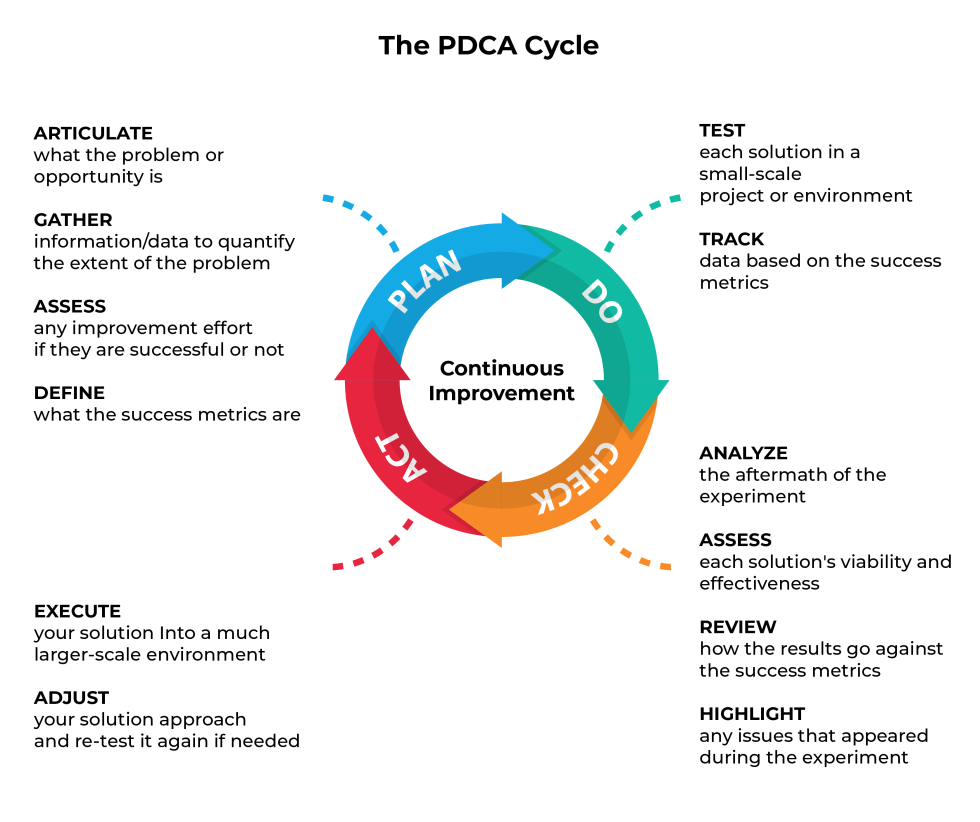

Plan

Plan is the process of setting goals and making plans. First, we set goals and then decide on the actions and evaluation methods to achieve them.

The key is to clarify 5W1H. 5W1H is an acronym for “When,” “Where,” “Who,” “What,” “Why,” and “How.” By summarizing the information using these elements, the content will be organized in a complete and easy-to-understand manner. It’s a good idea to collect information for your goal and then apply it to each element.

It is also important to set goals that are within the realm of possibility. If the goal is too difficult or the hurdles are too high, there is a risk that motivation will decrease due to the high level of difficulty. Avoid making the easy decision of “setting your goals high in order not to lose to your competitors.” Instead, make an appropriate plan after understanding your company and its current situation.

Do

Do is the process of putting into action what you have created in your plan. Let’s stick to the plan as much as possible here.

The key is to keep records of your actions, numerical results, processes, etc. Properly recording the results and processes will allow you to use them when reviewing later. Also, if you list things that didn’t go as planned and issues you faced during the actual experience, you will be able to understand the difference between the plan and reality.

Furthermore, when taking action, there is no need to force yourself to complete all plans. It is important to take small steps but steadily and conduct verification. By performing verification, you can confirm whether the action is valid or invalid, and it can also be used as reference material for subsequent analysis.

Check

Check (evaluation) is the process of checking whether or not actions were taken as planned. In this process, it is recommended to be as specific as possible using numbers. The more accurate this evaluation is, the more effective subsequent improvements will be.

The key is to not just check the results, but to dig deeper into the factors behind why things went well and why things didn’t work out. By digging deeper while checking quantitative data, you can improve the accuracy of your evaluation and make your subsequent actions more meaningful.

Action

In the action (improvement) process, based on the awareness and issues gained from checking, we will improve the content of our actions so that we can produce higher results. Let’s consider what measures we should take in the future and consider actions for further development.

When attempting to make improvements, there may be multiple actions that need to be reviewed. In that case, instead of trying to do everything at once, it’s best to prioritize your efforts. By starting with the highest priority items, you will be able to achieve your goals at a higher level.

5 benefits of using PDCA

PDCA is useful in a variety of situations, including business, but it can bring many benefits when used effectively. From here, we will explain the five benefits of using PDCA.

Possible to continuously improve business and operations

PDCA does not mean that you can do it once and be done with it; it is based on the premise of continuously accumulating feedback and improving things over the medium to long term. Therefore, the more we implement it, the more we are able to continuously improve our business and operations.

In addition, during the PDCA cycle, we not only focus on improving the bad parts, but also consider the good parts, including “Why did we get good results?” and “What can we do to make them even better?” , it will be easier to obtain hints that will lead to the development of companies and businesses. If a company can improve its operations, it will lead to improvements in the internal and working environment, and it will also be possible to create a comfortable working environment for employees.

Goals and tasks become clearer

If you run the PDCA cycle in an appropriate manner, your goals, tasks, and actions will become clearer, which will lead to better results. On the other hand, if goals are not set or challenges are not understood, the following situations can occur.

In order to make subsequent efforts meaningful, it is important to have clear goals and challenges.

Actions to take become clearer

In the PDCA cycle, goals, schedules, and priorities for what needs to be done are determined at the planning stage. If your priorities are not clear, your efficiency may drop significantly, but if you make a solid plan, the actions you need to take will be clear and you will be able to carry out your tasks and tasks more efficiently. When the priority order of what needs to be done is clear, there is less time spent wondering, “Which action should I take?” and you can take action quickly.

Clarifying what needs to be done will also help maintain motivation. It becomes easier to visualize achieving your goals and maintain a positive attitude toward them.

Gain the ability to achieve goals

One of the great benefits of using the PDCA cycle is that you can acquire the ability to achieve goals. Follow the PDCA process, including understanding the current situation, setting clear goals, making action plans, recording quantitative data, analyzing the next improvement plan, and taking actual actions toward that goal. You will develop the strength to achieve your goals.

Once you form a mindset of “why things went well” and “how to solve current issues,” you will be able to steadily achieve your goals with reproducibility. This ability to achieve goals can of course be used to achieve personal goals, but it can also be extremely useful when managing a team or managing departmental goals.

Develop know-how for business improvement

Corporate management and business development require constant improvement and improvement. Companies and businesspeople who cannot keep up with the trends of the times or cannot respond to change are likely to be weeded out.

Continuing to repeat the PDCA cycle requires constant attention to the current situation and goals, which leads to developing know-how for business improvement and business development. You will be able to respond flexibly to changes in the times and public opinion, and will be able to set appropriate goals and actions.

Disadvantages of PDCA

There are many advantages to using the PDCA cycle, but there are also disadvantages.

The purpose tends to be to perform PDCA

The purpose of PDCA is to improve operational efficiency and develop business, but there are many cases where people do not understand its essence and end up using PDCA as an end in itself. If you focus only on implementation without understanding the essence, you will not achieve any results. It is important to set objectives and goals and always remember them while proceeding with the PDCA cycle.

It is difficult to come up with new ideas that go beyond the framework.

PDCA is a process in which the measures and actions that have been taken so far are evaluated and analyzed, and then the next action plan or improvement plan is considered, so it is not suitable for honing creativity or creating new business. Not yet. Therefore, during the PDCA process, new ideas that go beyond the traditional framework tend to be difficult to come up with.

In recent years, with the wide variety of products and services available, it is impossible to compete with other companies without taking unprecedented initiatives. Sometimes you need to look into new genres or categories that have never existed before. If you want to come up with new ideas that go beyond the framework, you will need to adopt a different approach.

It takes time to improve

Since PDCA needs to be carried out after going through the cycle, the process to make improvements may take time. It is difficult to interrupt a plan even if a new issue arises along the way, and it is not easy to immediately take new action even if the situation changes. It can be said that it is difficult to quickly solve problems because it is only when you make the next plan that you can introduce new measures to deal with the problems discovered by taking action.

Why is the PDCA cycle considered old?

The PDCA cycle is often said to be “old,” “outdated,” and “meaningless.” If you want to improve your business using the PDCA cycle, you need to consider its shortcomings in advance and decide whether to take advantage of them or not.

It takes time to think from a medium- to long-term perspective.

The biggest reason why the PDCA cycle is said to be outdated is because it takes time to achieve the goal of business improvement. The problem is that it takes time to produce results because each cycle from planning to improvement needs to be repeated many times.

Since it is necessary to run the cycle from a medium- to long-term perspective, this framework is not suitable for people who want to achieve results in a short period of time.

The PDCA cycle itself can become an objective.

If the PDCA cycle is executed correctly and feedback is provided skillfully, it will certainly lead to business improvements. However, if the execution of the PDCA cycle becomes an end in itself, it will be difficult to achieve results.

If you run PDCA by inertia, you will not get any results. PIt is important to understand the purpose and be aware that each step of planning, execution, evaluation, and improvement leads to the next step.

While repeating the PDCA cycle, regularly review the operation of the PDCA cycle itself, create an operation manual, and share it within your organization to avoid operating it due to inertia.

Failure factors for each process

Despite carrying out PDCA, there are many cases where the results were not very effective or did not go well. From here, we will explain the causes of failure in each process.

Plan failure factors

Below is a summary of common failure factors in Plans.

The most important process is to understand and analyze the current situation, set future goals, and decide on actions and evaluation methods to achieve them. If we proceed with this point in a casual way, it will be difficult to maximize the effectiveness of PDCA. It goes without saying that if you don’t understand the current situation and set goals at the beginning, you will also be careless about your subsequent actions. Be sure to clarify the purpose of implementing PDCA, and plan the actions you need to take until you have a concrete image of how you will achieve your goals.

However, it is also extremely difficult to create a plan that has a 100% chance of coming true from the beginning. If you spend too much time making a plan and end up delaying action, or if you end up giving up before taking action, you’re missing the point. By repeating the PDCA cycle, you will be able to create a highly accurate plan, so it is important to have the attitude of moving forward with the plan first.

Factors causing failure of Do

Below is a summary of common failure factors in Do.

Acting without a plan is unlikely to yield much results. Deciding on specific details such as “what, how much, and by when” will make it easier to take action. If you don’t have a plan or take actions that are too difficult, you may find yourself wondering, “Is this plan or action really worth it?” and you may end up worrying more often. If you are clear about what you need to do, you will be less confused about what action you should take, and you will be able to take action quickly, so be specific when deciding on your actions.

Check failure factor

Below is a summary of common failure causes for Check.

It would be a waste to take action, but end up doing nothing, and not do any subsequent evaluation or analysis. Furthermore, even if evaluation and analysis are performed, if the content is vague and says, “It’s okay because it’s done well overall,” without checking numerical indicators, etc., it cannot be said that it will have an effective effect on subsequent efforts. Once you have made a plan and executed it, evaluate and reflect on it while checking quantitative data.

It is also important not to make decisions simply by looking at the results. By thoroughly identifying factors such as “why things went well” and “why things didn’t go as planned,” you can derive analytical results that can be used next time.

Action failure factor

Below is a summary of common failure factors in Action.

Even if you do evaluation and analysis and come up with the next action plan or improvement plan, it is meaningless unless you actually take action. Furthermore, even if a company-wide meeting is held, it remains at the level of “I wish I could do it someday” and if concrete actions are not planned afterward, the meeting itself becomes meaningless.

If you have come up with an action plan or improvement plan for future development, set a specific deadline and numerical goals to connect it to the next step. Note that when you are thinking about your next action, you may list more than one action. In such cases, prioritize and work on it.

Five points to effectively implement PDCA

PDCA is not very effective if you don’t do it correctly, but if you keep the key points in mind, you can effectively utilize it in your own work. From here, we will explain the key points to effectively implement PDCA.

Decide on specific goals and actions

It is important to be specific about your goals, actions, and plans. If your goals are difficult to understand or abstract, you are more likely to fail. If you set your goals and actions specifically using numbers, it will be much easier to visualize how you will achieve them.

For example, a goal that uses numerical values such as “Increase 5 new customers in month X and increase sales by 10% compared to last month” is better than a goal that says “Increase business sales in month X.” It becomes easier to imagine what actions to take.

Also, if you set numerical goals and then act on them, it will be easier to evaluate them and come up with suggestions for improvement. Having numerical data makes it possible to think about what to do and how much to do in the future.

Set achievable goals

Plans that ignore the current situation or goals that set too high a hurdle to achieve will make it difficult to know where to start, and there is a high possibility that it will be difficult to achieve results. Additionally, if you feel like you won’t be able to achieve your goals even if you take action, this can lead to a decrease in motivation.

When setting goals, be sure to set them at a level that is achievable. By keeping your goals within what you can achieve if you try hard, it will be easier to take action toward achieving your goals. It is recommended that you gradually increase the level of your goals as you continue to do so.

Avoid changing plans midway through as much as possible

Once you have set your action plan, try to move forward without making any changes as much as possible. If it is not carried out as planned, subsequent evaluations will not be able to proceed smoothly, and the process that took time may be wasted. Even if you don’t see results during the process, it is important to complete the project as planned without interruptions or changes as much as possible. The results may lead to new awareness of what went wrong. This awareness is extremely important in PDCA.

Also, during the implementation stage, it is a good idea to keep a record of the activities in order to improve subsequent evaluation and analysis. If you can produce specific numbers, such as sales results or sales, it would be even more effective to keep records with those numbers.

Visualize actions and deadlines

We recommend that you visualize the actions and deadlines you have decided on. No matter how carefully you plan at the beginning, if you don’t understand the next steps or deadlines, or if there are omissions, you will naturally be far from achieving your goals.

When running a business, you may be faced with a huge amount of work, but it is not easy to memorize the details in your head alone, so if there is no visualization, you may end up missing something unexpected. I don’t know. To prevent this from happening, it is important to devise ways to confirm actions and deadlines at any time. For example, use the following methods to ensure that the PDCA cycle goes smoothly.

Regularly check the situation and perform evaluation/confirmation

Generally, PDCA is carried out in parallel with regular work, but if you are too busy with regular work to carry out evaluations, the speed of the cycle will slow down. Be sure to incorporate time into your daily schedule to check the situation and evaluate/confirm the situation from time to time.

Please check the progress toward the original goal and the situation on the site, and check if there are any problems. If you incorporate it into your daily routine, you can quickly run the PDCA cycle.

Management methods other than PDCA that are attracting attention

Although PDCA can be expected to be very effective, in recent years a different type of management method has appeared. From here, we will explain the management methods that are currently attracting attention.

OODA

OODA is an acronym for Observe, Orient, Decide, and Act, and is pronounced OODA. Like PDCA, it is used as a method to improve business operations and produce good results.

OODA is also called “OODA loop”, and you can go back to the previous stage if necessary, or restart the loop from any stage. In the PDCA cycle, the four processes of Plan, Do, Check, and Action are progressed in order, whereas OODA has a high degree of freedom. I am. This requires quick judgment in each case, but it has the advantage of being able to make decisions quickly.

OODA will be effective in situations where the external environment changes rapidly and quick and accurate decision-making is required.

Benefits of OODA

OODA has advantages that the PDCA cycle does not have, so if you want to improve your business, choose it appropriately according to your situation. The OODA loop can cancel out the disadvantages of the PDCA cycle, and is recommended for those who feel that the PDCA cycle is not suitable or has no meaning, or for those who are concerned that it takes too much time. The benefits of OODA are as follows.

- Easy to take measures tailored to the situation

- Tailored to customer needs

- The cycle to improvement is fast

I will explain each in turn.

Easy to implement measures tailored to the situation

OODA is a loop, not a cycle, so you can go back to any step and try again if something goes wrong or you can skip a step.

In this respect, PDCA cannot be retried unless it is evaluated and improved in one cycle, making it difficult to implement measures tailored to the situation and changes, so OODA may be more suitable.

If you need to respond flexibly, you can expect flexible and speedy business improvements by adopting OODA.

OODA’s strength lies in its ability to make and implement decisions on-site. Therefore, if a problem occurs, you can resolve it as quickly as possible depending on the situation.

Tailored to customer needs

OODA is resilient to change and adapts to new ideas, allowing us to immediately incorporate customer needs.

On the other hand, in the case of the PDCA cycle, plans must be carefully devised at the planning stage, and revisions must be made over many cycles, which limits the scope for responding to customer needs.

As a result, the PDCA cycle cannot withstand sudden changes in specifications requested by customers, and there is a risk that all the accumulated work will go back to square one.

When there are many requests from customers or for projects that have just started, OODA is more suitable because it allows decisions to be made while observing the site.

The cycle to improvement is fast

With OODA, you can see the on-site situation and make adjustments immediately, and there is no need to run loops in an orderly manner, so you can get some results in a short period of time.

OODA is more suitable when you need to produce results in a short period of time because it solves the major bottleneck of the PDCA cycle, which is that it takes a long time to see results from business improvements.

Additionally, since OODA is a trial-and-error system, it does not take time for upper management and operations personnel to make decisions. This is also one of the reasons why we can achieve results in a short period of time.

There is no need to return to the observation stage after execution, and you can respond flexibly according to on-site judgment. As a result, we can loop around and make improvements in a short period of time.

STPD

STPD is an acronym for See, Think, Plan, and Do, and is a management method for improving business operations.

Unlike PDCA, which starts with a plan, STPD first looks at the current situation and understands it before starting. Therefore, after clarifying concerns and risks, you can think about future plans and actions. By thoroughly analyzing the current situation before making a plan, you will be able to avoid the mistake of setting goals that are impossible to achieve.

However, STPD does not have a process to verify its effectiveness after implementation. As a result, it is often impossible to evaluate or look back, and therefore cannot judge whether or not the plan or action was correct. Reflecting on your actions is a very important element, so be sure to consciously set aside time for reflection.

Corporate examples of PDCA

toyota motors

Toyota Motor is now a global company that has established a solid position in global. The PDCA at the Toyota Motor has built a car production method as P (Plan) to eliminate the “Muri Muda Mura” in the field as much as possible.

In D (Do (action)), a system that uses a “Just in -time” method that produces the required amount when necessary, or automatically stops the machine to prevent defective products from being produced. has been done.

C (CHECK (verification)) stopped production when defective products were detected and signs of the problem came out. We will proceed with verification at once with the staff (administrator / worker).

A (ACTION) has a technician, administrator, and worker integrated to make an improvement proposal, and builds a flow that can be incorporated immediately.

Ryohin Keikaku

In the Ryokan Plan, there are manuals that make use of PDCA to flatten the know -how so that the quality of services such as customer service is not made in stores and staff members. P (plan (planning)) is that there is a business based on this manual “Muji Gram”. On the premise of this manual, it is transferred to D ((execution)), and the results and awareness of actually working on the action are C (CHECK). Repeated improvements while sharing that awareness, and connect to A (improvement). Those that have led to improvements are reflected in “Muji Gram” and the manual will be revised. “Muji Gram” has always been updated and has not been completed until the end. This concept itself has increased customer satisfaction and achieved high -leveling services.

Ateam

There is an A -team Co., Ltd., which operates a business with three pillars of lifestyle support business (comparison / information site), entertainment business (smartphone game), and EC business. As an analysis for maximizing the effects in the SEO measures that the Headm is working on every day, there is no page query that has been significantly increased or decreased in inflow, or the user behavior has changed, or CTR for the average ranking. I am looking at whether it is not low.

Among them, I have noticed a mechanism that makes it easier to turn PDCA when there is an increase or decrease in traffic by centrally managing queries with an external tool.

In addition, by keeping various data, we turn PDCA by making it easier to increase and decrease queries and traffic.

Related article:

A -team’s SEO Strategy -Data Analysis and Foundation Creation-

summary

In this article, we explained the outline of PDCA, the four processes, the merits and demerits, and the points that effectively perform PDCA.

PDCA is a very effective method for companies and businessmen who want to solve issues, improve business, and achieve their goals. In recent years, there have been negative opinions on PDCA, but it seems that there are many cases where the effect is not felt because it is implemented in the wrong way. If you adopt it properly, you can still expect the effects as a means of continuously improving your work.

Please be aware of the points to be held about each process, turn the cycle, and connect to your results.