PDCA is an indispensable

framework

for improving business efficiency and reflecting it in results.

However, in the age of speed following the spread of the Internet, the PDCA cycle is often said to be outdated because it does not fit the business content.

Here we have provided an easy-to-understand explanation of PDCA, which many people have an anachronistic image of.

What is PDCA?

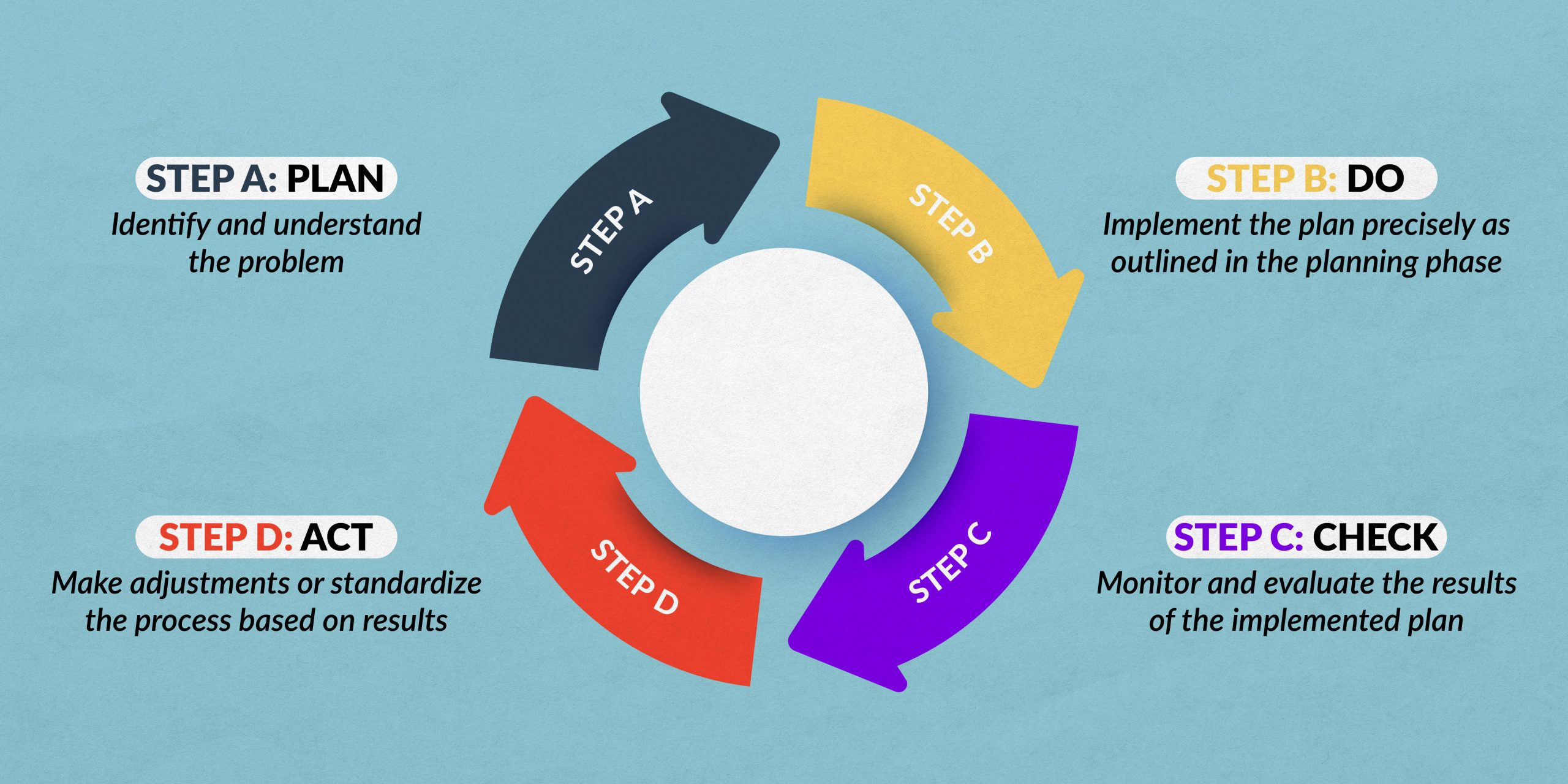

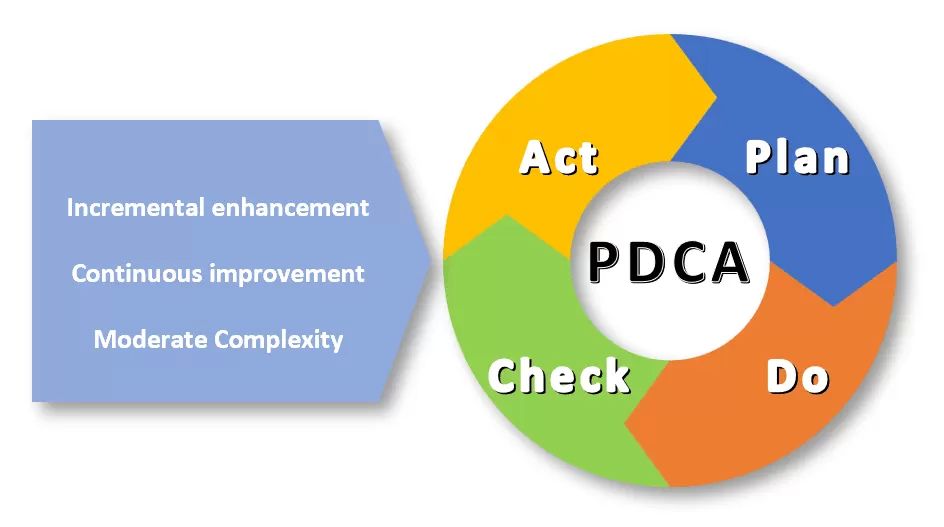

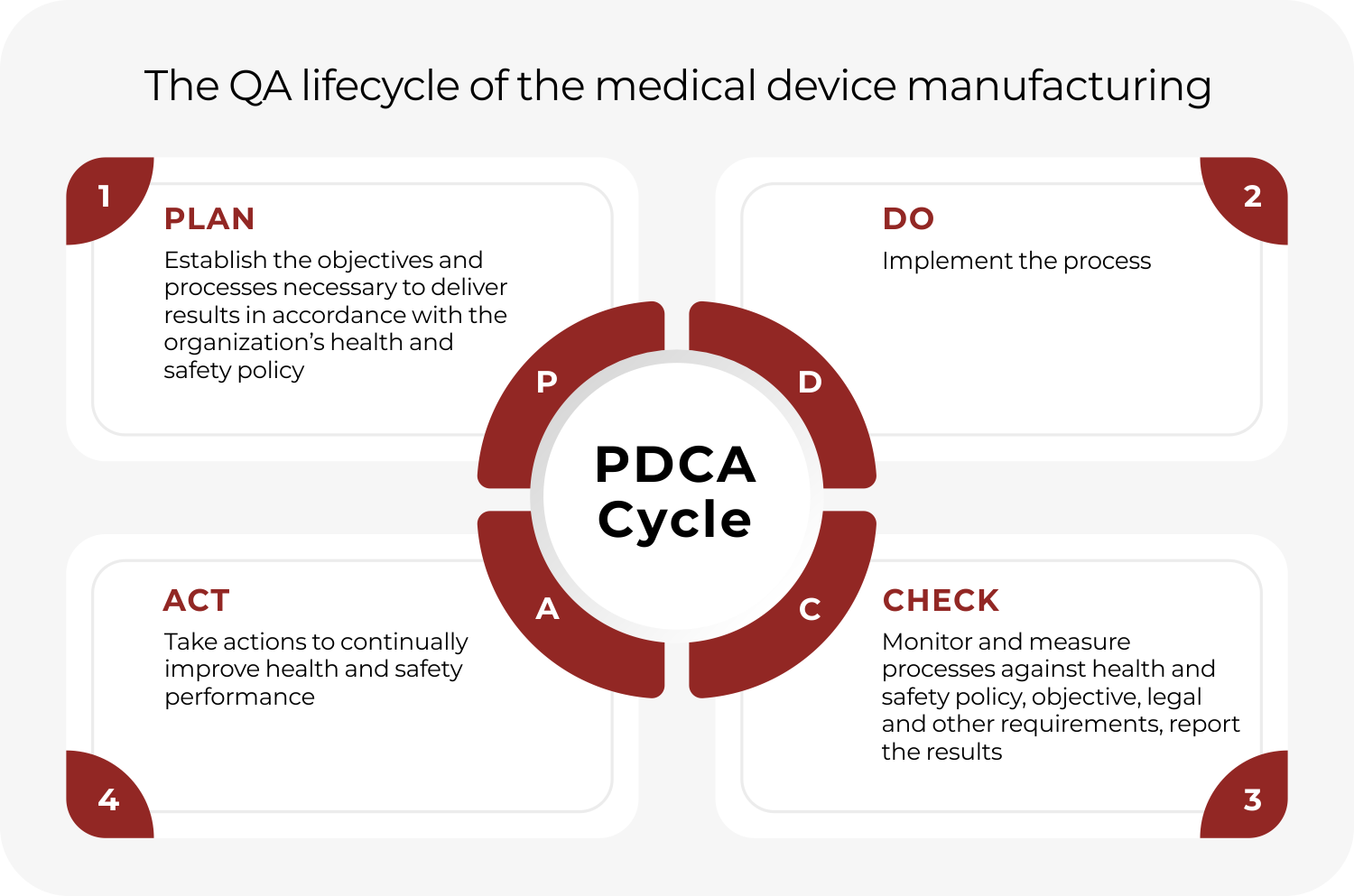

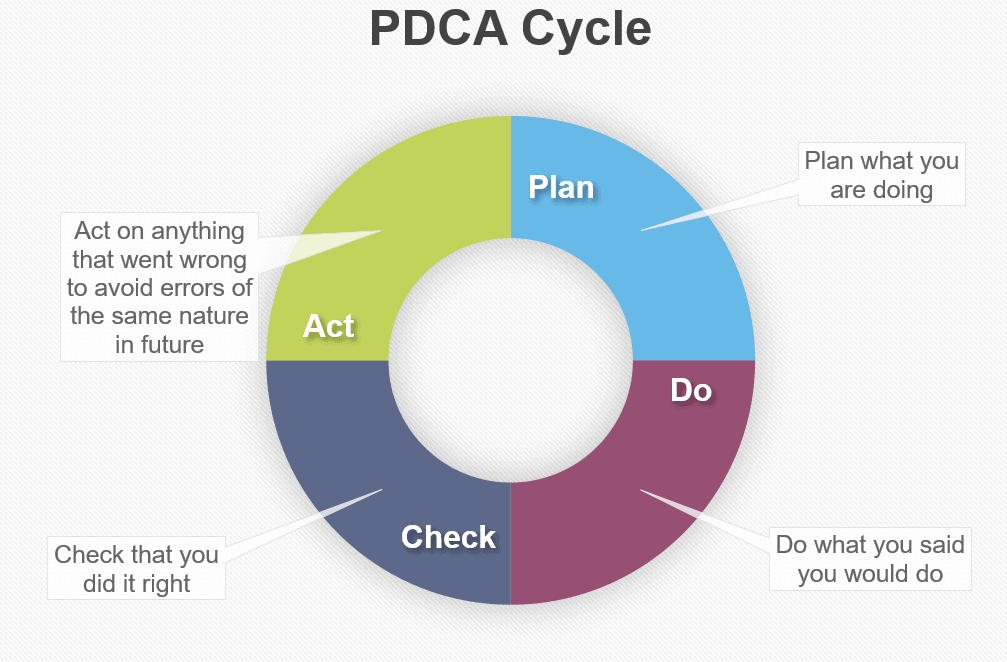

PDCA is an abbreviation made up of the following initials:

- Plan: Plan

- Do: Execute

- Check: Evaluation

- Action: Improvement

This is a framework for improving work content and increasing efficiency to increase productivity.

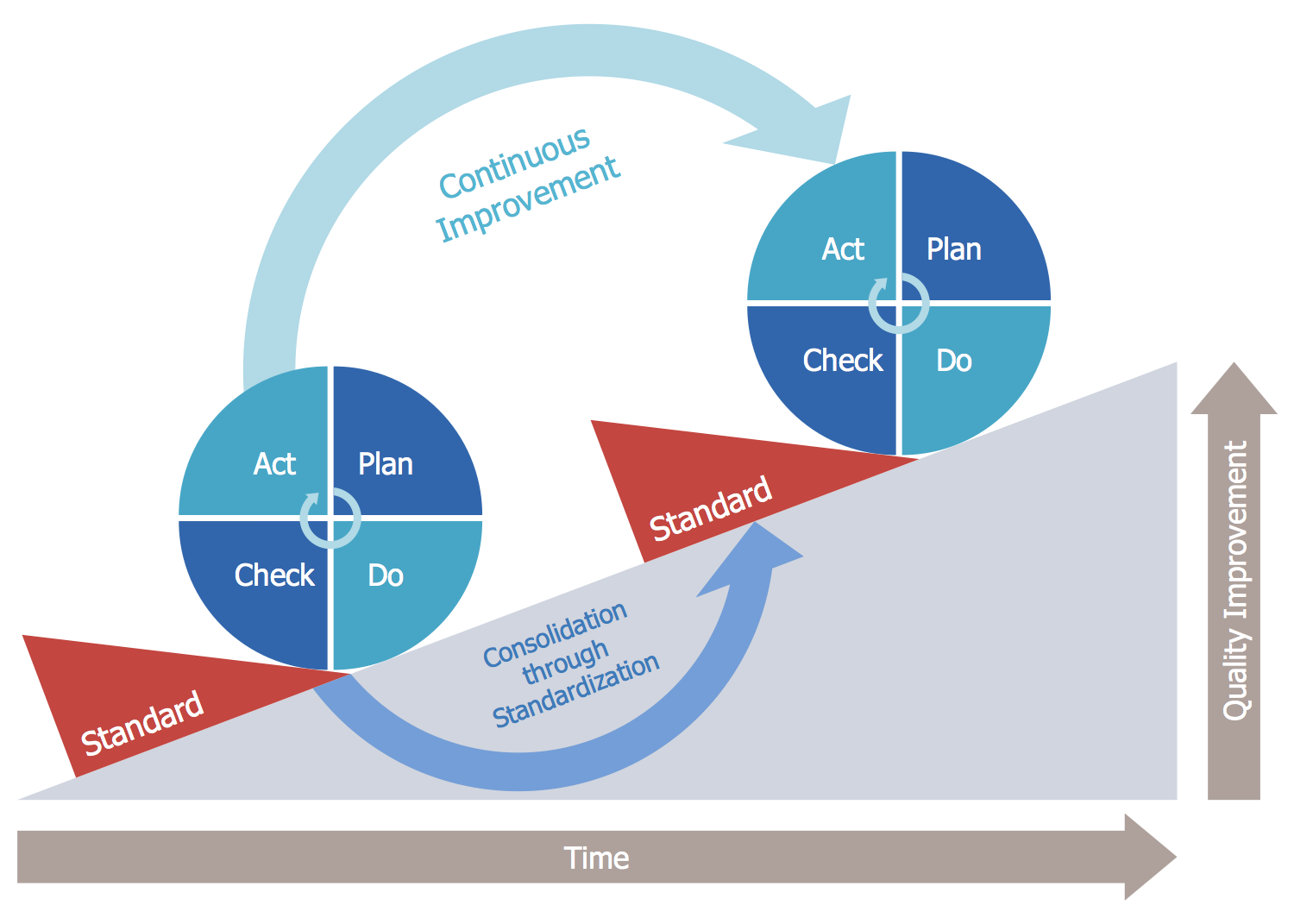

Work and verification are performed in the order of “P → D → C → A”, and when the process is completed up to “A”, return to “P” again.

This cycle is called the “PDCA cycle” and is repeated over a long period of time.

Plan: Plan

“Plan” is the planning stage of the business. We will set goals and create an action plan to achieve those goals.

The “Plan” that is the starting point of the PDCA cycle is an important factor that influences the subsequent “DCA” cycle.

If this is not properly formulated, it will be difficult for the subsequent cycle to be effective, and it may end up being a waste of effort.

To avoid this, it is important to be aware of

frameworks

such as 5W1H, set KGIs and KPIs, and set deadlines.

Do: Execute

In “Do”, you will put into action the action plan you created in “Plan”. Create to-do lists and subdivide tasks to ensure action is taken.

The certainty of actions for this factor will greatly influence the subsequent KGI and KPI values.

However, whether or not KGIs and KPIs can be achieved is a matter of results, and is not something that employees can control.

On the other hand, the execution of the action plan is something that can be controlled by the company, and it is no exaggeration to say that the effectiveness of the “Do” will determine the success or failure of achieving the goals.

Check: Evaluation

In “Check,” we look back at whether the action plan has been implemented properly and evaluate to what extent we are approaching or achieving our target values.

At the same time, if you are not approaching or achieving the target value, we will examine the reasons why you are not approaching or achieving the target value.

“Check” often focuses on the reasons why the goal was not achieved, but by evaluating the factors when the goal was achieved, new solutions may be found.

Action: Improvement

In “Action”, we will try to make improvements based on the evaluation in “Check”.

If we determine that we are approaching or achieving our target values, we will continue to maintain the previous PDCA cycle while incorporating the newly discovered points for improvement.

If the evaluation is not favorable, we will search for and identify improvement plans and try to make improvements.

If it seems that no improvement can be expected, we will consider whether to go back to the current PDCA cycle and review it from scratch, or cancel the plan altogether.

Is PDCA outdated? Why is PDCA considered outdated?

The PDCA cycle method was proposed by American statisticians Dr. William Edwards Deming and Dr. Walter Andrew Shewhart in the 1950s.

Although the proponent was an American, it was actually a Japanese company that actively adopted the PDCA cycle. This PDCA cycle works particularly well in the manufacturing industry and has been introduced by many companies.

Post-war Japan was a time when the PDCA cycle method was adopted by many manufacturing industries, and it could be called the heyday of the PDCA cycle.

Postwar Japan’s manufacturing industry led the world, and its high quality and brand power helped rebuild Japan after the war.

At that time, the Internet was not widespread, and the PDCA cycle, which took place over six months to a year, worked well together.

However, as the Internet began to spread and the historical background and things changed rapidly, the slow cycle of PDCA gradually became unsuitable for the current speedy era.

This is why the PDCA cycle is said to be old. In addition, the rise of highly effective frameworks such as “PDR” and “OODA” that can replace PDCA is one of the reasons why PDCA is said to be outdated.

PDR replaces PDCA

One of the drawbacks of PDCA is its slow cycle. It is necessary to repeat the cycle every six months to a year or more, and a long verification period is required.

“PDR” was created to compensate for this shortcoming. This is a framework proposed by Linda Hill, an American professor at Harvard Business School. It has the feature that the cycle operating period is much shorter than PDCA.

What is PDR? PDR is an abbreviation of the following initials:

- Prep: Preparation

- Do: Execute

- Review: Evaluation = review

Prep: Preparation

The “P” in PDCA was Plan, but in PDR it is replaced by “Prep”.

In other words, there is no “Plan” in the PDR cycle, and it means that preparations must begin immediately.

In order to start implementing the plan, we will briefly prepare the plan by setting goals, researching competitors, and analyzing the market.

Do: Execute

“D” stands for “Do” as in PDCA, and the plan is put into action based on the results of the investigation and analysis conducted at the “Prep” stage.

In PDR, instead of making a detailed plan and executing it like “creating a to-do list” or “subdividing work” like in PDCA, we start with the idea of moving towards achieving the goal. .

Review: Evaluation = review

In place of the omission of “Check (evaluation)” and “Action (improvement)” in PDCA, “R (evaluation)” is included in PDR.

Both “Check” and “Review” mean “evaluation”, but there are differences in how they interpret “evaluation”.

“Check = evaluation” in PDCA means “confirmation of progress,” but “Review = evaluation” in PDR has a stronger meaning of “reviewing the results after execution.”

From PDCA to PDR and OODA

Like PDR, “OODA” has emerged as a framework that can replace PDCA. Like PDR, it is characterized by the ability to significantly shorten the cycle operating period.

This is called a “loop” instead of the “cycle” that was called until PDR. It was proposed by John Boyd, an American fighter pilot and aviation tactician.

What is OODA?

OODA is an abbreviation made up of the following initials:

- Observe: Observe

- Orient: Hypothesis construction

- Decide: decision making

- Act: Execute

Observe: Observe

In OODA, the loop begins with “observing”. This does not mean simply “looking”, but rather gathering information while assessing the situation.

We casually collect facts such as trends in the field, the position we are in, and the surrounding environment.

OODA is a framework that emphasizes current situational judgment, and is said to be able to adapt well to uncertain and ambiguous environments. In recent years, it has attracted attention in the business world as an effective means to realize co-creation, which is the key to adapting to change in the VUCA era.

Orient: Hypothesis construction

In “Orient = Hypothesis Construction”, we will construct a hypothesis based on the information collected at the “Observe = Observation” stage.

Since you can freely formulate a hypothesis, including your own beliefs, it is necessary to prepare multiple hypotheses and select the one that you judge to be most appropriate for the current situation and environment.

Depending on the choice of this hypothesis, the result of the final action (act) will vary greatly.

The key to building better hypotheses is to incorporate past mistakes. Then, we further develop a hypothesis that improves this, leading to improvements in the next loop.

Decide: decision making

In “Decide”, a decision is made by selecting the most suitable hypothesis from among the multiple hypotheses established in “Orient”.

We comprehensively consider market trends, our company’s position in the market, competitors, etc., and reconfirm what we want our company to become. In addition to making decisions, we also firmly decide what our company will do.

Act: Execute

In “Act”, we carry out the contents agreed in “Decide”.

OODA is a framework that is used in rapidly changing backgrounds and environments. Therefore, the situation may have changed since the initial information gathering stage, “Observe”.

However, they serve as new information and will become the material for operating the next OODA loop.

Even if the situation changes, we will carry out the agreed upon decision up to “Decide” as usual, and incorporate new information into the next OODA loop operation.

What are the benefits of PDCA?

Although PDCA is said to be old, it is a framework that works effectively for processes and processes that are well defined.

The main benefits of properly utilizing PDCA are as follows.

- Advantage 1 of PDCA: It becomes clear what to do

- Advantage 2 of PDCA: Identification of issues

- Advantage 3 of PDCA: You can get closer to achieving your goals

Advantage 1 of PDCA: It becomes clear what to do

By building a PDCA system, you can visualize the work content and clarify what needs to be done.

Once what needs to be done is clarified, goals are created, and all employees can work together from the same perspective to achieve those goals.

In any large company, if what needs to be done is ambiguous or the goals are unclear, employees will not be able to work in accordance with those needs and will not be able to take concrete measures.

In order to avoid becoming a company as a company without knowing where we should end up, we will firmly establish a PDCA cycle and clarify what needs to be done.

Advantage 2 of PDCA: Identification of issues

Once the PDCA cycle has been running for a certain period of time, issues that need to be resolved may emerge.

In PDCA, targets are set numerically or quantified in the first “Plan” stage.

For example, set visualized target values using specific numbers, such as “increase sales target from 100 million yen to 200 million yen” or “increase equity ratio from 40% to 50%.”

If the target values are visualized, you can clearly see at a glance whether or not they have been achieved in the “C” “Check” after the PDCA cycle is in operation.

If something has not been achieved, it will be easier to identify what elements are missing, and as a result, it will be easier to find issues that need to be overcome.

Advantage 3 of PDCA: You can get closer to achieving your goals

PDCA is a framework that allows you to understand the gap between the current situation and your goals and improve the negative aspects while comparing them. This will greatly contribute to shortening the time it takes to achieve your goals.

What you need to do will be clarified, and you will be able to understand “what your company needs to do” and “what your company can do to deal with the negative aspects.” By steadily solving these problems, you can get much closer to achieving your goals.

How to make PDCA work well

The following are ways to make PDCA work well.

- “Plan” involves quantifying and setting specific target values.

- Don’t finish it in one PDCA cycle, repeat it.

- If things do not go well, review and adjust the contents of the PDCA.

“Plan” involves quantifying and setting specific target values.

As I have already mentioned, when setting the “Plan” in PDCA, if you set the goal by specifically quantifying it or quantifying it, you will be able to operate the subsequent cycle efficiently. .

A less-than-desirable example is setting abstract goals such as “expanding the company” or “increasing profits.”

If you do this, you will lack specificity and will not be able to understand what needs to be improved and how.

Repeat without finishing with one PDCA cycle

The same is true for the PDCA cycle, PDR cycle, and OODA loop, but the cycle does not end after it has started once, but it is necessary to repeat the cycle.

After starting from “P” and operating up to “A”, we will examine the points for improvement and actually try to make improvements, then we will start from “P” again.

By repeating this process over and over again, you will gradually improve your work and get closer to achieving your goals.

If things do not go well, review and adjust the contents of the PDCA.

Of course, even if you actually run the PDCA cycle and continue to run it for several cycles, things may not go well. In that case, we will review the contents of the PDCA and repeat adjustments.

If this still does not lead to results, consider reversing the PDCA plan or canceling the plan altogether.

Furthermore, in today’s rapidly changing background and environment, the PDCA cycle may not be appropriate for your company’s business content.

In that case, it may be easier to produce results by switching to a framework such as PDR or OODA.

summary

Although “PDCA” is said to be old, it still works effectively for things that have well-defined processes. In particular, the effectiveness of PDCA in the manufacturing industry has already been verified and proven by many companies.

If you can use it freely along with “PDR” and “OODA” on a case-by-case basis, you will be able to shorten the path to achieving your goals.