The “PDCA cycle” is a method suitable for improving business efficiency. However, the PDCA cycle is sometimes said to be old-fashioned and sometimes cannot be put to good use in the field. Therefore, we will introduce a comparison with new methods, points to be careful of when implementing the PDCA cycle, improvement measures, and examples from actual companies.

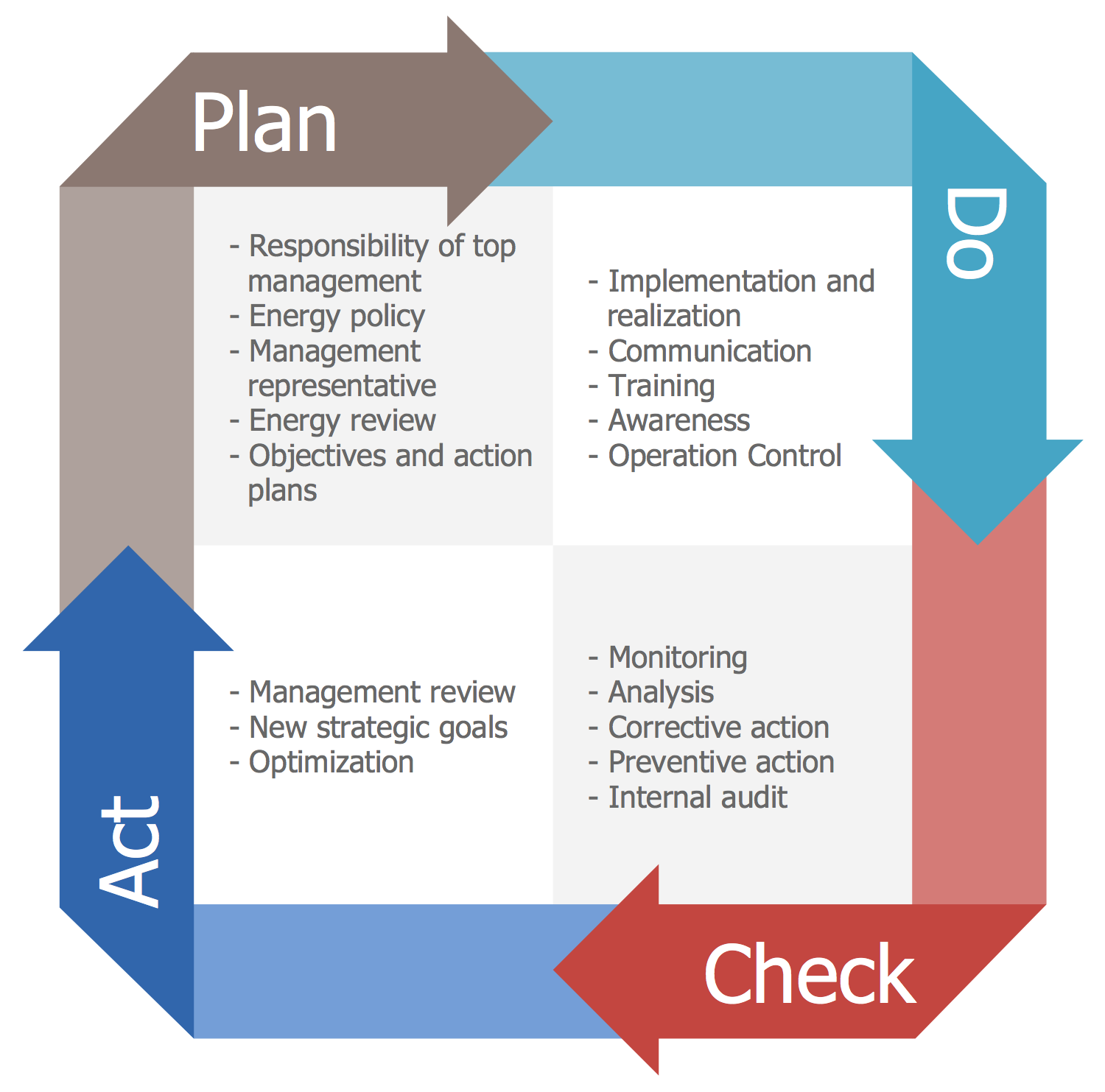

What is the PDCA cycle?

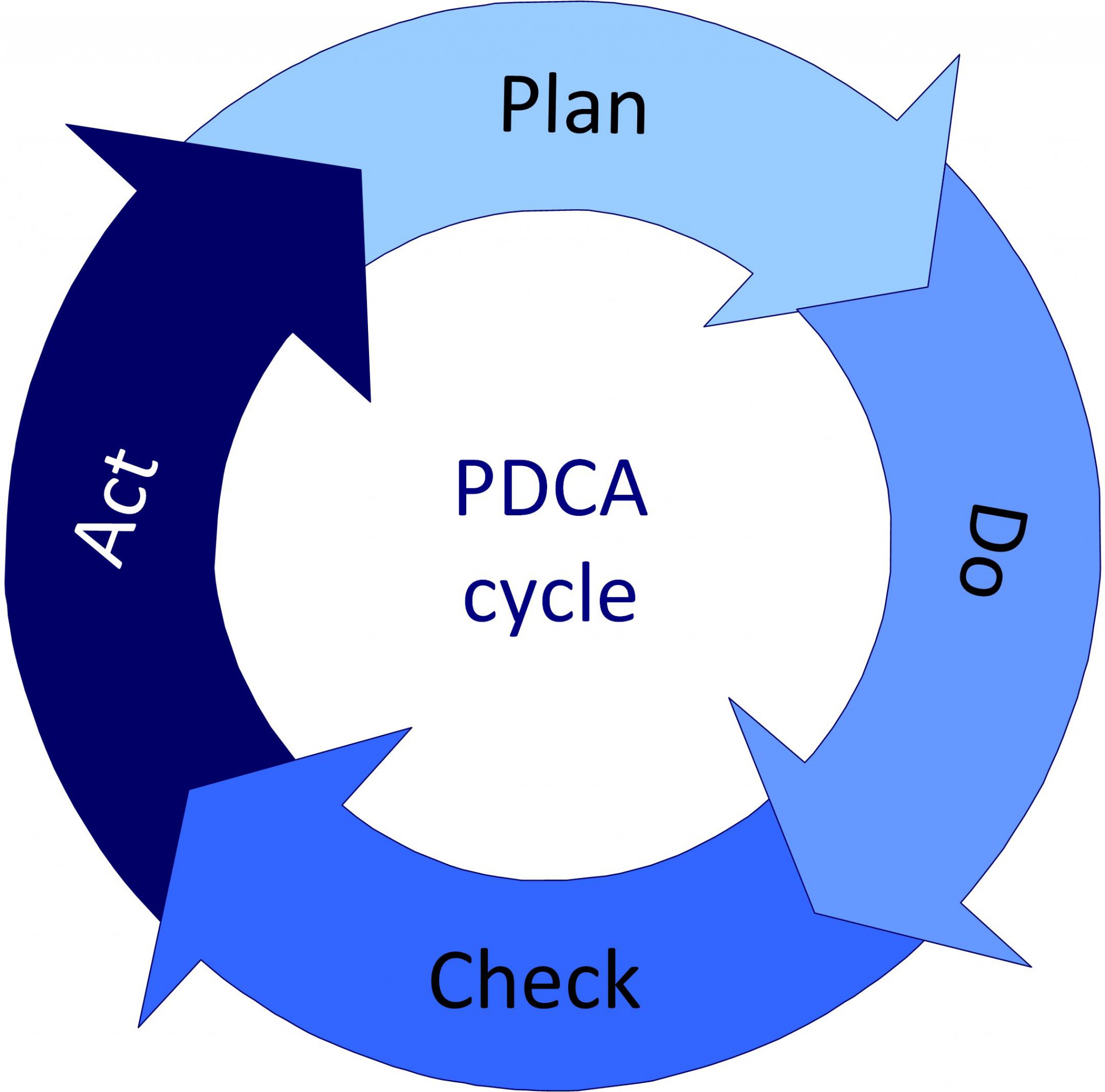

The PDCA cycle is an acronym for Plan, Do, Check, and Action, and it cycles through four stages to improve work efficiency in order to achieve goals. It refers to the method of improvement.

In fact, the PDCA cycle is practiced by many companies and is used not only in marketing but also in various operations.

Plan

This is the phase where you set goals and develop an action plan to achieve them.

Example of implementation

<br/>Sales: Collaborate with other departments to strengthen approaches to existing customersFood and beverage: Think of new menus and courses to acquire customers

Web marketing: Deciding on search keywords

Do

This is the phase of implementing the plan you have made as planned.

Example of implementation

<br/>Sales: Take a new approach based on data collected in other departments Food and beverage: Create and serve a planned menu

Web Marketing: Optimize your site

Check (evaluation)

After executing the plan, this is the phase where the actual results are compiled and the results are analyzed.

Example of execution

<br/>Sales: Verify the number of inquiries, sales, number of applications, etc.Food and beverage: Analyze all kinds of information such as menu sales, time periods when orders increased, customer demographics, etc.

Web marketing: Verify search ranking, number of accesses, CV rate, etc.

Action (improvement)

This is the phase where improvements are made based on the analyzed data and lead to the stage of planning again.

Example of implementation

<br/>Sales: Pick up data that is missing from the approach Food and beverage: Add menu items with increased sales to the regular menu

Web marketing: Improvement based on evaluation

Background why the PDCA cycle is said to be “old”

PDCA has been adopted by many companies as a method suitable for streamlining and improving business operations, but as new methods have appeared, PDCA is now considered outdated.

Similar new method

| OODA | An acronym for Observe, Orient, Decide, and Action. A method of first observing customers and the market, determining the situation, formulating a plan for what to do, and implementing it in order to achieve a goal. |

| STPD | An acronym for See, Think, Plan, and Do. A method of grasping the facts, then thinking about what to do, planning, and implementing it. It is easy to plan and has a quick cycle because it is based on a single fact and is considered when making a plan. |

| DCAP | An acronym for Do (execution), Check (evaluation), Action (improvement), and Plan. Although the order is different from PDCA, the content is the same. Used in new business or work in unknown areas, where action is required first. |

PDCA and new methods differ in order, speed of achieving cycles, reproducibility, etc. DCAP is very similar to PDCA, but the order is different. PDCA puts planning first, but DCAP puts execution first. In other words, rather than thinking, we act first, then reflect and make improvements.

Each method has its pros and cons, so rather than viewing them as superior or inferior, or new or old, understand the characteristics of each and adopt the method that suits your company.

Advantages of PDCA cycle

・Goals and action items are clear and efficient

・Improvement items are clear

・Make it a habit to verify and improve processes

It is well known that implementing the PDCA cycle will lead to business improvements, but we will introduce you to the actual benefits. Please decide whether it is suitable for your company rather than just trying to introduce it.

Goals and action items are clear and efficient

The PDCA cycle is a method of setting goals in advance and working towards them, making it clearer and more efficient. By setting goals, you automatically know what to do, so you don’t have to work blindly.

Improvement items are clear

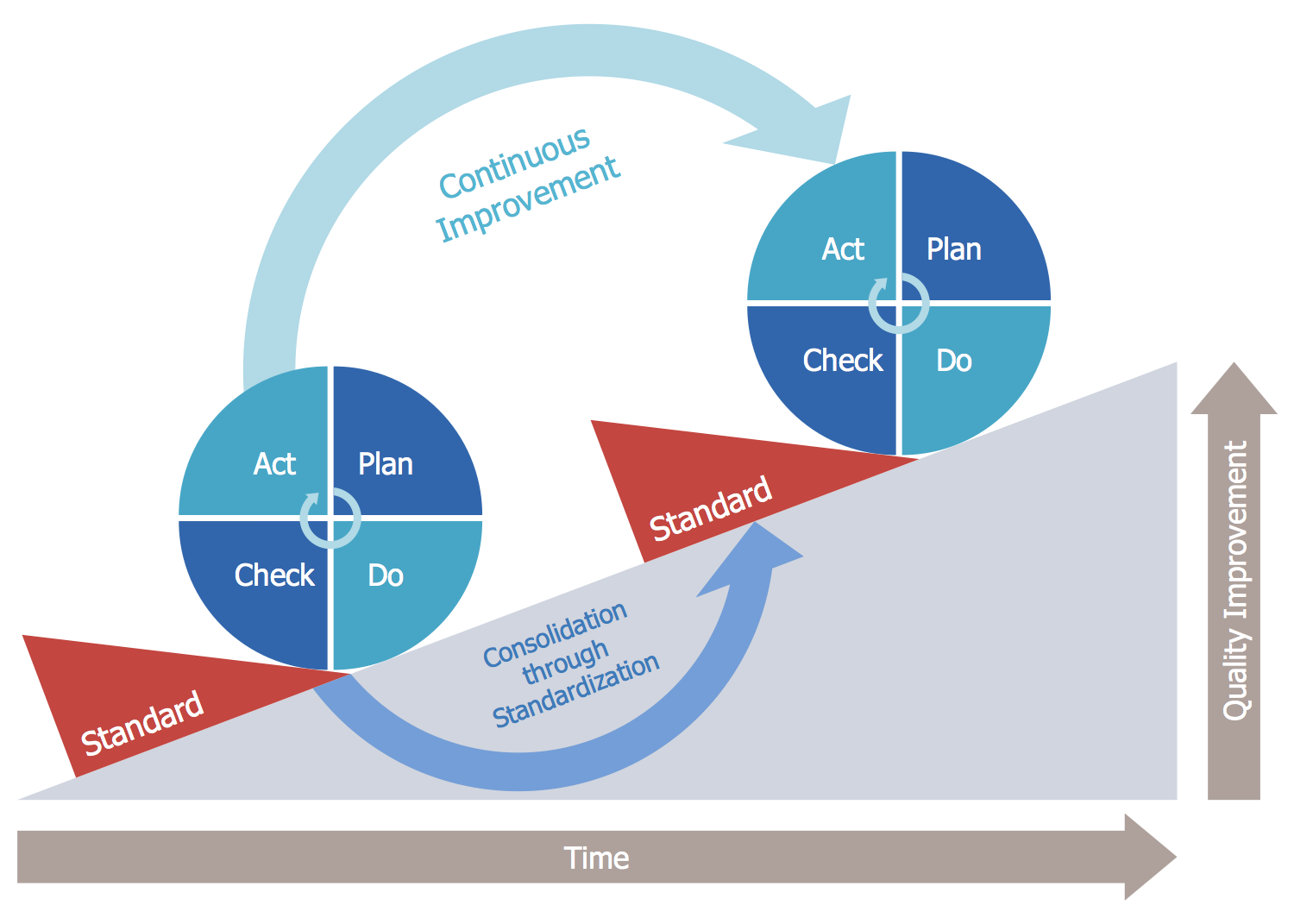

This has the advantage of making it easy to understand what actions were taken and the results, and highlighting areas that need improvement. Once you complete one cycle of PDCA, you will know what tasks and actions to take next, and it will be easier to continue making further improvements.

Make it a habit to verify and improve issues

If you look back at what went well and what went wrong, and work to improve it, you will reduce the number of mistakes. If you continue the PDCA cycle, verification and improvement will become a habit, so you will be able to act based on “what should be done” without having to take time to make a plan.

Common failure examples and improvement measures in the PDCA cycle

・There will be backlash due to its introduction.

・The amount of work increases

・Settings for each item and each goal become unclear

・Difficult to respond to unexpected situations

・New innovations are difficult to generate

Despite working on the PDCA cycle, some companies feel that it does not lead to improved operational efficiency or that it is not suitable for their company. Let’s understand specific improvement measures along with examples of failures.

There will be backlash due to its introduction.

When introducing a new method called the PDCA cycle, there may be opposition from frontline employees. People tend to feel anxious about things they don’t understand when their environment changes or they take on a new challenge, so let’s clarify what we want to achieve by introducing the PDCA cycle and work together.

Improvement measures

- Plans should be open to eliminate employee concerns.

- Present benefits to employees

The amount of work will increase

There are also concerns that the introduction of the PDCA cycle will increase the workload. It is important to always follow the plan to avoid burdening your employees. Make a detailed plan, try to visualize your workload, and try to allocate tasks appropriately.

Improvement measures

- Make a detailed plan and visualize the work that needs to be done

- Allocate tasks evenly

The settings for each item and each goal become unclear.

The first step in the PDCA cycle is to make a plan, but if you don’t know exactly when you’ll reach your goal, your motivation will drop. When planning, set deadlines to determine what needs to be done by when and eliminate any ambiguity.

Improvement measures

- Set a goal deadline

- Set deadlines for each process

Difficult to respond to unexpected situations

Since the PDCA cycle requires planning at the beginning, it is difficult to respond to unexpected situations, which is a bottleneck. Take notes and record each time, and use it as one of the improvement measures for the next cycle. As the cycle continues, employees’ experience will increase, more things will proceed as planned, and fewer unexpected situations and failures will occur.

Improvement measures

- Always keep records in case of an emergency.

- Always look back

- Lead to the next improvement measure

New innovations are difficult to generate

The PDCA cycle is originally a method for improving quality and business content, so it is not a method for creating something new that has not yet appeared in the world. Therefore, the basic rule is not to work on tasks that are not in the plan or sudden things that come up on a whim. On the other hand, it is said that it is difficult to generate “innovation” in the form of new business models and ideas.

If you come up with a new idea, it’s a good idea to actively incorporate it into the next cycle, or repeat small cycles to minimize failures.

Improvement measures

- Actively incorporate new ideas when taking improvement measures

- In some cases, adopt a method that changes the order, such as a DCAP cycle.

Successful example of PDCA cycle

In fact, there are many companies that have successfully implemented the PDCA cycle. What kind of innovations did successful companies use in their PDCA cycles?

Ryohin Keikaku

Ryohin Keikaku, which operates MUJI, has been working to make the PDCA system take root. He says he has established a PDCA system that allows any store manager to create the best sales floor.

In addition, in some cases, DCAP was adopted, starting from Do (execution) rather than Plan. Although PCDA has the disadvantage of lacking flexibility, it is a unique method that emphasizes Do (execution), and basically it seems that they were given free rein. The committee met once a week to come up with improvement plans and established the PDCA cycle.

Softbank

A major feature of SoftBank’s PDCA cycle is that it proceeds with multiple cycles in parallel. This is a method of setting big goals with a short deadline and smaller goals with short-term deadlines, and verifying them every day.

Also, although PDCA has the disadvantage of making it difficult to generate new innovations, a major feature of SoftBank is that it incorporates ideas that come up into plans as much as possible and implements them.

It is called “ultra-high-speed PDCA,” which runs many PDCA cycles in a short period of time because it runs multiple cycles in parallel and sets small goals that lead to achieving big goals.

toyota motor vehicle

Toyota Motor Corporation has adopted a method called “Toyota-style 5W1H,” which is a combination of PDCA and OODA, and can be said to have created an opportunity for many companies to adopt the PDCA cycle.

It is characterized by thinking deeply about why something happened, and it is a method of repeating the why five times and then thinking about what needs to be done. This is an idea typical of Toyota, which has strived to thoroughly eliminate waste.

Summary: Arrange the PDCA cycle to suit your company

The PDCA cycle, which has been successfully practiced by many companies, is a reproducible method that anyone can use to improve business efficiency and clarify goals. Although it is sometimes called “old” these days, new ideas may be born when devising improvement measures after planning and execution.

It is a good idea to start by establishing the PDCA cycle and repeating reviews and improvements.