Do you know the term “digital twin”? If you are involved in the web for business, many of you may be using it.

Digital twin is an advanced technology that represents various digital copies of people and things in cyberspace, and is attracting attention as technology rapidly evolves. This technology is being used in a variety of situations, including manufacturing, logistics, and urban development, and it is predicted that Japan will continue to develop as a country with this technology being used even more in the future.

In this article, we will explain the overview of digital twins, the benefits of using them, the situations in which they are used, and the potential for future development. Digital technology will be incorporated into society in the future, so let’s deepen our understanding so that we can use it in our own lives, work, and solving corporate problems.

What is a digital twin?

In recent years, digital twins have been attracting attention in a variety of situations, and are being used to solve social issues and improve the quality of work. First, I will explain the meaning and overview.

Advanced technology that expresses various digital copies of people and things in cyberspace

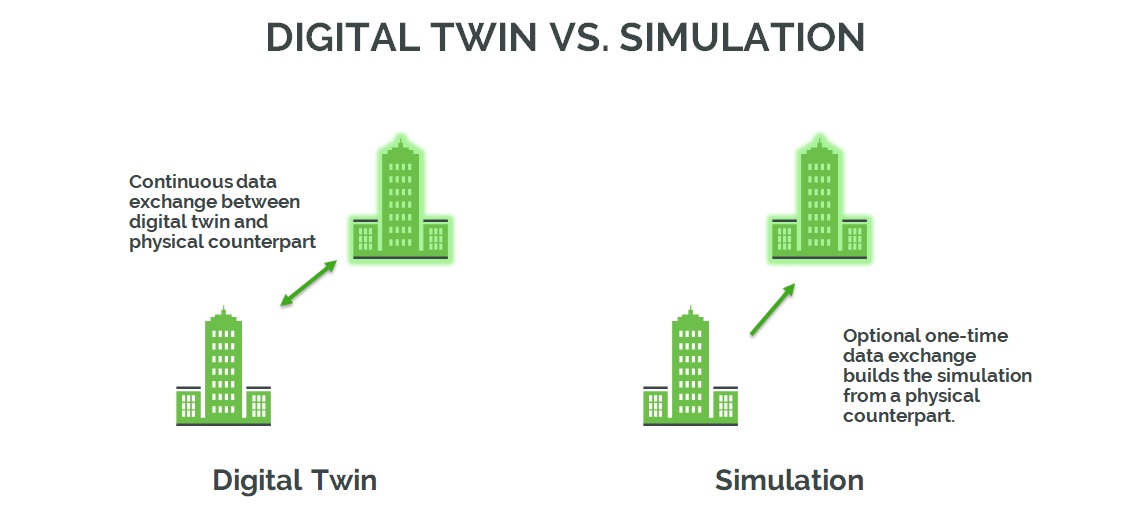

Digital twin is a technology that represents various digital copies of people and things in cyberspace. It is called a “digital twin” because it creates a digital data copy that is exactly like the one that exists in reality. In this cyberspace, it is possible to perform simulations such as analyzes and future predictions based on digital data, making it possible to consider the optimal methods and actions based on the results.

Background that attracts attention

The spread of IoT is a major reason why digital twins have started to attract attention. IoT is an acronym for “Internet of Things,” and is a general term for technologies that connect various devices to the Internet and communicate with each other. By communicating with each other, information can be shared, enabling purposes such as automation and remote control.

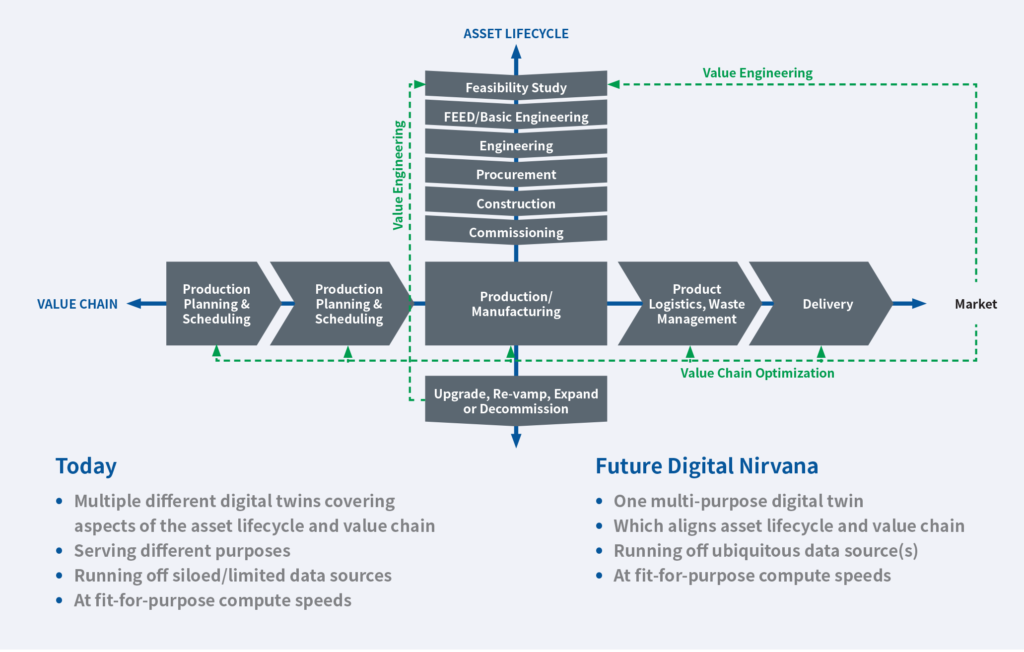

Digital twins have existed since the 1960s, but in order to digitize information, human resources were required for input/output work, which was a huge burden. However, with the dramatic evolution of digital technologies such as IoT in recent years, the degree of reproducibility and resolution of real space in virtual space has improved significantly, and this has attracted a lot of attention. Even today, this technology is used in a wide range of fields, such as manufacturing, logistics, power generation equipment, and the automobile industry, offering endless possibilities.

The number of companies that are considering introducing it is increasing because they have discovered great potential. However, there are still very few Japanese companies introducing it, and it is likely that Japan will see significant development from this point forward.

Differences between simulation and metaverse

Similar concepts include “simulation” and “metaverse,” but each of the three has different characteristics.

Simulation refers to performing verification by substituting something else when it is difficult to test using the actual thing. Therefore, a digital twin can be considered a part of simulation. However, unlike digital twins that reproduce real space in virtual space, simulations are not necessarily executed in virtual space such as on a computer. We sometimes conduct tests at experimental sites using models that are easy to visualize. Additionally, a digital twin collects real-world data at each moment and changes it according to changes in the real world, but simulations do not have the ability to collect real-world data at each moment. Not necessarily.

Next, the Metaverse is a virtual world built on digital space. It is consistent with a digital twin in that it is “built on a digital space,” but in the Metaverse, activities are carried out using characters called “avatars,” which are alter egos of oneself used for communication. Furthermore, whereas a digital twin is essentially a reproduction of the real world in a virtual space, a metaverse may also construct a world that has no relation to reality or adds elements that are not supposed to exist. .

Benefits of using digital twins

Digital twins are a technology that is already being used in a wide range of situations, including manufacturing, logistics, power generation equipment, the automobile industry, and urban planning, and are being used to solve corporate issues and social problems. Here we will explain five main benefits of digital twins.

Quality improvement

Digital twins, where everything is completed in a virtual world, facilitate trial and error, making it possible to repeat product prototyping at low cost. This makes it possible to identify small defects and add functions to improve usability, leading to improved quality of finished products. In addition, since AI analyzes the large amount of data obtained through the use of IoT, highly accurate data can be obtained, making it easier to more precisely discover areas for product improvement and points that are difficult to use. .

cost reduction

It is also possible to carry out the prototyping process in a virtual space that reflects the real environment. In the past, the process of implementing these measures required repeating the measures many times to complete the product, incurring various costs such as a lot of time, manpower, and money. However, since prototypes can be developed and produced in a virtual space, costs can be significantly reduced compared to producing many prototypes in the real world. Data from a prototype once produced can be used in the next design and development, reducing the number of prototypes needed and the time required for development. Shortening development time means reducing personnel and costs, leading to cost reductions in a variety of ways.

Equipment maintenance/preventive maintenance

Preventive maintenance is where digital twins are most commonly used in manufacturing. When an abnormality occurs in factory equipment, etc., the various installed sensors accurately report the situation in real time, making it possible to collect and analyze data and isolate the cause of the error or breakdown. Predictive maintenance, which predicts future failures from accumulated information, is also possible.

In traditional manufacturing sites, after a problem occurs, it is necessary to verify and revise the design based on reports from the manufacturing department and feedback from the client, making it difficult to carry out development and manufacturing smoothly. I did. By using technology, it is possible to quickly identify the cause and make improvements using data collected at each moment.

risk reduction

Another major advantage is the ability to reduce risks at the manufacturing site. Developing a product can be very costly, and there are cases where the product cannot be realized even after spending a huge amount of money. If this cannot be achieved at such a high cost, there is a risk that the company will suffer major losses.

By using a virtual space that faithfully reproduces the physical space, you can actually conduct prototyping and verification during production within the virtual space. Therefore, it is possible to develop and manufacture products with lower risk than creating prototypes in the real world.

Enhanced after-sales service

It can also be used to enhance after-sales services such as maintenance of products provided to clients.

Previously, if a problem occurred while a client was using a product, the client had to contact the manufacturer or repair company for a repair request or confirmation. However, if technology is introduced and it becomes possible to check the usage and consumption status based on the data sent from the product, it will be possible to send notifications when measures such as parts replacement or maintenance are required. Masu. For example, it is possible to understand the wear and tear of the battery and the friction caused by the use of the product, and provide after-sales services such as battery replacement at the appropriate time. You can expect to gain more trust and trust from your clients, as well as improve customer satisfaction.

Technologies used in digital twin

Digital twins are used in a variety of situations, and various technologies are used to make them more accurate. The following five are mainly used.

IoT

IoT is an acronym for “Internet of Things,” and it is a general term for technologies that connect various devices to the Internet and communicate with each other. By communicating with each other, information can be shared and used for purposes such as automation and remote control.

IoT is an indispensable technology for collecting data from the actual physical space in order to create a virtual space. Data collected through IoT devices is used to construct a virtual space via the Internet. For example, by reflecting information on equipment and equipment acquired by sensors and other devices via the Internet, it is possible to recreate the real world with greater realism and precision.

A.I.

AI is an acronym for “Artificial Intelligence” and is an artificial reproduction of human intelligence. It is generally called “artificial intelligence”. Computers and systems can learn from large amounts of data, derive correlations and rules, and use these to solve problems and problems.

With digital twins, it is now possible to analyze the real world created in virtual space with high precision using AI. In addition to improving AI’s ability to process information, the increased amount of data due to the development of IoT has increased AI’s learning capabilities, making it possible to make more accurate predictions of the future.

AR/VR

AR is an acronym for “Augmented Reality,” and VR is an acronym for “Virtual Reality.” AR, which is a technology that augments the real world by adding information, and VR, which allows virtual spaces to look like the real world, are also becoming indispensable technologies. Visualizing glitches and errors that occur in virtual space provides more realistic feedback to the real world. Additionally, AR/VR can be used to provide training and support for work, which will have a positive impact on companies.

5G

5G is an acronym for “5th Generation” and refers to the fifth generation mobile communication system. The service started in Japan in 2020, and it is an essential technology for the use of digital twins as it has the characteristics of high speed, large capacity, low latency communication, and multiple simultaneous connections. Compared to the previous generation of 4G, communication speeds are now approximately 20 times faster, and even larger amounts of data can be communicated. Because 5G allows large amounts of data to be communicated at high speed and with low latency, it is possible to create a system that allows data to be reflected in virtual space at each moment.

CAE

CAE is an acronym for “Computer Aided Engineering” and refers to an engineering support system that uses computers to design and analyze products.

It has been used in the manufacturing industry from an early stage because it can significantly reduce costs and shorten time compared to actually producing a prototype. Due to the dramatic evolution of technology, the resolution of the real space that is reproduced has improved dramatically, and it has become possible to realize sophisticated simulations at each moment while using huge amounts of data. It is used in conjunction with the digital twin.

Scenes where digital twin is used

The use of digital twins has begun in various fields, and it won’t be long before they become familiar to us. It is actively used in various industries including manufacturing. From here, I will explain the scenes in which it is used.

manufacturing industry

Digital twins are often used very often in the manufacturing industry. It is used to solve problems faced on-site and improve productivity, such as improving product quality, reducing costs when producing prototypes, and detecting problems in advance. For example, it will be possible to test things in virtual space that are difficult to test in real life, such as production plans related to production volume and inventory, and equipment abnormality detection.

Additionally, efforts have recently begun to create a digital twin of the entire manufacturing line to optimize robot operations and logistics systems. It is now possible to expect greater operational efficiency and cost reductions.

Logistics industry

In the logistics industry, digital twins are used to create virtual warehouses that are recreated moment by moment, to make operations more efficient, and to optimize logistics design and management. It is no exaggeration to say that thanks to this technology, logistics are carried out smoothly.

In addition, efficient logistics management is becoming possible by using data obtained from sensors on vehicles to track and visualize logistics processes, such as predicting traffic jams, managing inventory, and verifying transportation routes. Masu. The logistics industry will continue to develop in the future and will have a positive impact on our lives.

power generation equipment

Digital twins are also used in power generation equipment, contributing to more efficient operations. Power generation equipment is essential to our daily lives, and in order to reduce the burden on the environment, it has become a challenge to further streamline operations and improve operating rates. However, the bottlenecks in making this a reality were personnel issues and high costs. Meanwhile, advances in technology have made it easier to monitor the operating status and maintenance status of equipment. By using digital twins, we can detect inefficiencies, areas for improvement, and risks of defects at an early stage, and manage them with less burden.

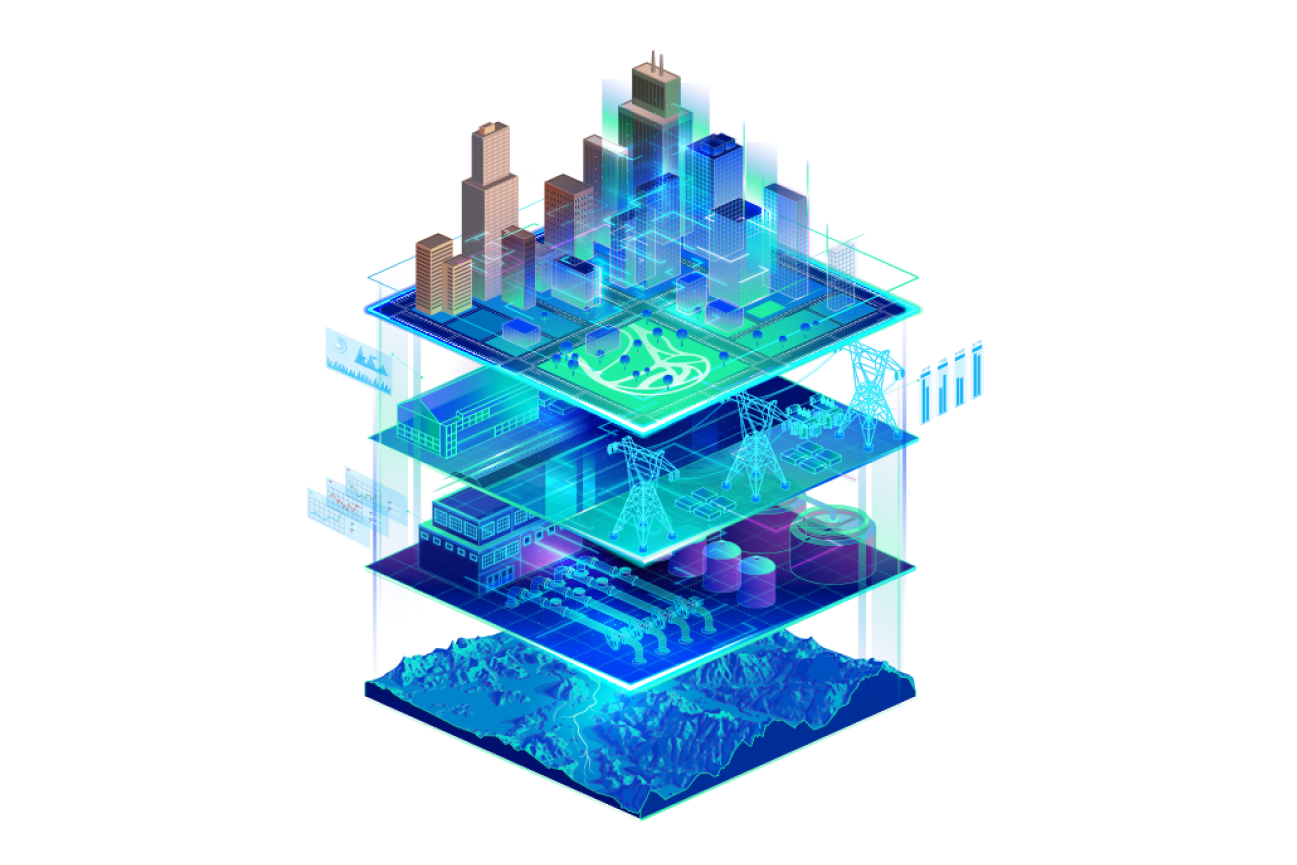

urban planning

In recent years, technology has also been used for urban development and station area development. With a digital twin, it is possible to create a large-scale virtual city that integrates static data such as roads, buildings, and lines within a city, as well as dynamic data such as the flow of people and energy consumption in the city. It becomes. We create virtual cities that imitate real cities and conduct simulations to improve the sustainability and efficiency of cities.

These technologies are also being used to design smart cities. A smart city is a livable city that utilizes cutting-edge communication technologies such as AI and IoT to improve the sophistication and efficiency of urban functions and services. For example, by creating a virtual city using data on population, traffic congestion, construction, etc., it becomes possible to simulate urban development. This initiative is even being used in projects by Japan’s Ministry of Land, Infrastructure, Transport and Tourism. We can see that the whole country is using this technology to create a better society.

healthcare services

It has also begun to be used in the healthcare and medical fields.

For example, by incorporating sensors and cameras into medical equipment and linking them with a digital twin, real-time visualization of surgeries will become possible. Being able to perform surgery from a variety of perspectives allows us to maximize performance even in slightly difficult surgeries, which may increase the possibility of saving many patients.

It can also be used to manage information and conditions regarding individual patients, and to monitor and predict disease progress. By acquiring information on a patient’s health and vital signs at every moment, it will be easier to create a disease treatment plan tailored to the patient and build a warning system, which will lead to improved quality of medical care. It will be.

How will digital twins develop in the future?

Digital technology is used in a variety of fields and scenes, and it is thought that it will not be long before it becomes a familiar part of our daily lives. It will continue to develop and make our lives and work even smoother. From here, we will explain the current market size and future prospects.

market size

According to a report published by Research Station LLC, the global market size of digital twins is estimated to rapidly increase from US$6.53 billion in 2021 to reach US$6.9 billion in 2022 and US$73.5 billion in 2027. I am. (

https://www.dreamnews.jp/press/0000269376/

)

Factors contributing to the growth of the market include the further use of technology in the manufacturing industry to reduce costs and improve supply chain operations, and the demand for technology in the healthcare industry that will further accelerate the market. This is because it is believed that

further development in many areas

The combination of technologies such as digital twins, IoT, AI, machine learning, etc. is expected to further accelerate market growth and develop in more fields. The future of digital twins is almost limitless, with an ever-increasing number of technologies being applied to a variety of new applications all the time. This means we can continuously generate the insights needed to improve products and streamline processes, creating the best practices for businesses and digital technology users. However, the number of Japanese companies that utilize digital twins is still small. Compared to 80% to 90% of American companies, only 10% to 20% of Japanese companies use digital twins. It hasn’t been done yet. There are still some aspects that are not fully understood, but as understanding deepens, further utilization and development will likely take place.

Issues that can be expected to be solved by digital twins

Digital twins are an advanced technology that represents various digital copies of people and things in cyberspace, and it is believed that by using them, we can solve a variety of problems in the world. From here, we will explain the issues that can be expected to be solved.

social issues

Digital twins are expected to play a role in predicting global social issues such as the SDGs and optimizing solutions. SDGs is an abbreviation for “Sustainable Development Goals,” which was adopted at the United Nations Summit in September 2015, and is a set of 17 goals set by 193 United Nations member countries to be achieved over the 15 years from 2016 to 2030. It’s a goal. Our goal is to solve social issues such as poverty, environmental issues, discrimination, and human rights issues.

For example, when quickly discovering social issues that may arise in the real world and providing feedback on solutions, such as evacuation drills assuming weather disasters, improving evacuation behavior, and resolving labor shortages due to the aging of the workforce. You can use these techniques to

medical issues

In the medical field, biodigital twins are expected to solve problems in the medical field. A biodigital twin is a system that captures various body data obtained through medical examinations, tests, and daily life into a computer as digital data, and uses digital twin computing technology to create a precise mapping or biological model in cyberspace. It’s something that exists.

The collected data will be used to assist medical professionals, including simulating surgeries and treatments. This technology is also useful for early detection and prevention of diseases. This technology will significantly improve medical technology and contribute to increasing the number of people who are saved from illness and who live healthy lives.

summary

In this article, we have explained the overview of digital twins, the benefits of using them, the situations in which digital twins can be used, and the potential for future development.

Digital twin is an advanced technology that expresses various digital copies of people and things in cyberspace, and as technology rapidly evolves, it is attracting attention along with the metaverse. The global market size has rapidly increased from 6.53 billion USD in 2021, and is estimated to reach 6.9 billion USD in 2022 and 73.5 billion USD in 2027, and is expected to continue to grow.

It has not yet been fully adopted by Japanese companies and is still in the process of development, but considering the trends of the future, there will be a big difference between companies that have adopted it and those that have not.

Utilizing technology can have a big impact on solving your company’s problems, so let’s start by catching up on the latest information.